ביצור טבק, שימור רמות טמפרטורה ולחות מדויקות הוא חיוני לאיכות עקבייה של המוצר. כאשר מערכות קירור ישנות נאבקו לעמוד בצרכים הדורשניים של עיבוד טבק, שדרוג מקיף הפך לנחוץ כדי להבטיח ייצור מתמשך ואיכותי.

בקרת טמפרטורה והומידיות : על מנת שمنتجات הטבק יתאימו לתקני איכות, חשוב מאוד לשלוט בטמפרטורה ובלחות בדיוק גבוה. תנודות יכולות לגרום לרמות לחות לא אחידות בעלים של הטבק, מה שמשפיע על המוצר הסופי.

עמידות ואמינות בהתחשב בלחות הגבוהה ובחשיפה הפוטנציאלית לחומרים קורוזיביים בסביבת המפעל, המערכת החדשה הייתה צריכה להיות חזקה, עמידה לאורך זמן ועמידה בפני שחיקה.

יעילות אנרגטית : למערכת המשופרת היה צורך להיות יעילה אנרגטית, כדי להפחית את עלויות התפעול ולהתאים למטרות של קיימות.

מערכת מיזוג האוויר הקודמת שהותקנה כבר לא הייתה מסוגלת לשמור על התנאים המדויקים הנדרשים, מה שהוביל לאי-יעילות בייצור וכיבויים מזדמנים. הפתרון החדש היה צריך לא רק לעמוד בסביבת הדרישה הגבוהה של המפעל, אלא גם לספק בקרת סביבה מדויקת ועקביות.

הפתרון כלל התקנת יחידות טיפול באוויר (AHUs) בעלות קיבולת גבוהה, שתוכננו להפיץ את האוויר באופן אחיד ברחבי אזורי ייצור גדולים וצפופים. על ידי הבטחת זרימה מתמדת של אוויר, הצליחה המערכת לשמור על רמות טמפרטורה וرطوبة עקביות, גם במהלך תקופות ייצור כבדות.

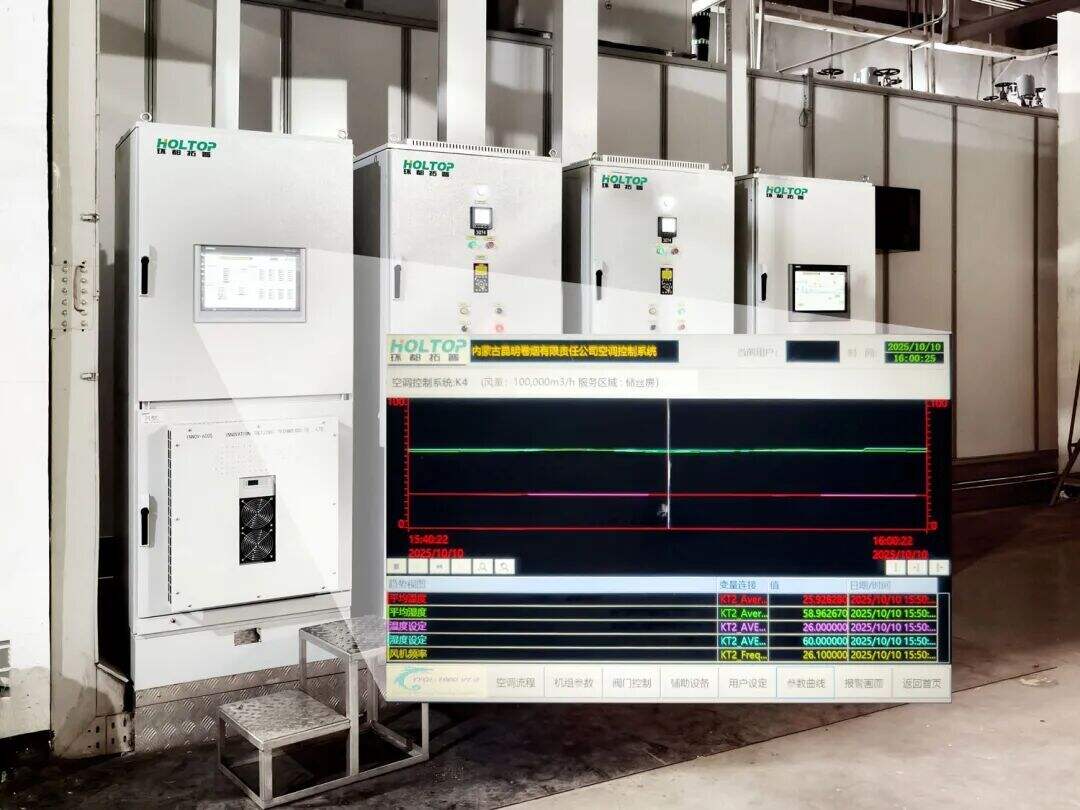

מומש نظام בקרה דיגיטלי מתקדם לניהול מדויק של טמפרטורה ורطوبة. מערכת זו משתמשת באלגוריתמים מתקדמים ובנתונים בזמן אמת מהחיישנים כדי לשמור על תנאי עבודה אידיאליים, מה שקריטי לשמירה על עקביות המוצר ולצמצום הפרעות בייצור.

בהתחשב באופי סביבת עיבוד הטבק, הכוללת חשיפה לחומצות וחומרים קורוזיביים אחרים, תוכנן המערכת החדשה באמצעות חומרים עמידים בפני שחיקה כדי להבטיח אורך חיים ארוך ולמזער את הצורך בתיקונים תכופים.

איכות מוצר עקבית : על ידי שמירה על טמפרטורה וرطوبة אידיאליות, מבטיחה המערכת החדשה רמת לחות אחידה בעלים הטבק, מה שמביא למוצר סופי עקבי יותר.

יעילותperation : עם פחות תקלות והפרעות במערכת, הפקסיליה יכולה לפעול בצורה חלקה יותר ולהפיק בכושר גבוה יותר.

חיסכון בעלויות תחזוקה : החומרים עמידי השחיקה שהשתמשו בהם במערכת החדשה מקטינים משמעותית את צרכיי התפעול והתחזוקה ומאריכים את מחזור החיים של הציוד.

בעוד שמערכת מיזוג האוויר החדשה מציעה ביצועים משופרים, תחזוקה מתמדת היא המפתח להבטחת יעילות מתמשכת. בדיקות שגרתיות של רכיבי המערכת כגון מסננים, חיישני לחות ומשאבות עוזרות לזהות בעיות פוטנציאליות בהקדם, וכך מונעות תקלות לא צפויות ותיקונים יקרים.

טיפ תחזוקה שגרתית היא הכרחית כדי לשמור על הפעלה יעילה של המערכת ולמנוע תיקונים יקרים או periods של הדחק.

עם מערכת מיזוג האוויר החדשה, מפעל הטבק יכול לשמור על תנאים יציבים ואמינים יותר, גם כאשר טמפרטורות חיצוניות משתנות. בקרת אקלים עקבית זו היא חיונית לאופטימיזציה של איכות המוצר ולשמירה על הפעלת המפעל ביעילות מרבית.

שדרוג מערכת מיזוג האוויר במפעל הטבק הביא לשיפורים משמעותיים באיכות המוצר וביעילות התפעול. על ידי אבטחת תנאים סביבתיים יציבים, שיפר המפעל את תהליך הייצור, הפחית את זמני העצירה ומזער את עלות התפעול. שדרוג זה אינו רק תומך בייצור בר-קיימא, אלא גם ממוקם המפעל להצלחה ארוכת טווח בה đápota לדרישות הגוברות של תעשיית הטבק.

חדשות חמות

חדשות חמות2026-02-10

2025-12-25

2025-12-25

2025-12-01

2025-11-18

2025-11-13

כל הזכויות הזכויותights שמורות Reserved © 2025 על ידי בייג'ינג הולטופ קירור בע"מ - מדיניותICY