Maximizing Energy Efficiency in Industrial HVAC Systems

HVAC systems in industrial settings eat up a big chunk of operating budgets for manufacturers and big facilities alike. When companies boost the energy efficiency of their heating, ventilation, and air conditioning setups, they save money while also doing their part for the environment through reduced carbon output. Many plants have found that switching out old equipment for modern high-efficiency AHUs makes a real difference. Some reports suggest savings around 20% to maybe even 30% on energy bills. These improvements work best when combined with VSD technology which adjusts motor speeds based on actual needs rather than running at full power all the time.

The Role of Energy Efficiency in Reducing Operational Costs for Industrial HVAC

Energy-efficient HVAC systems minimize electricity use through optimized components like advanced compressors and heat exchangers. According to a 2025 industrial energy report, facilities adopting these upgrades see payback periods as short as 3–5 years due to reduced utility bills.

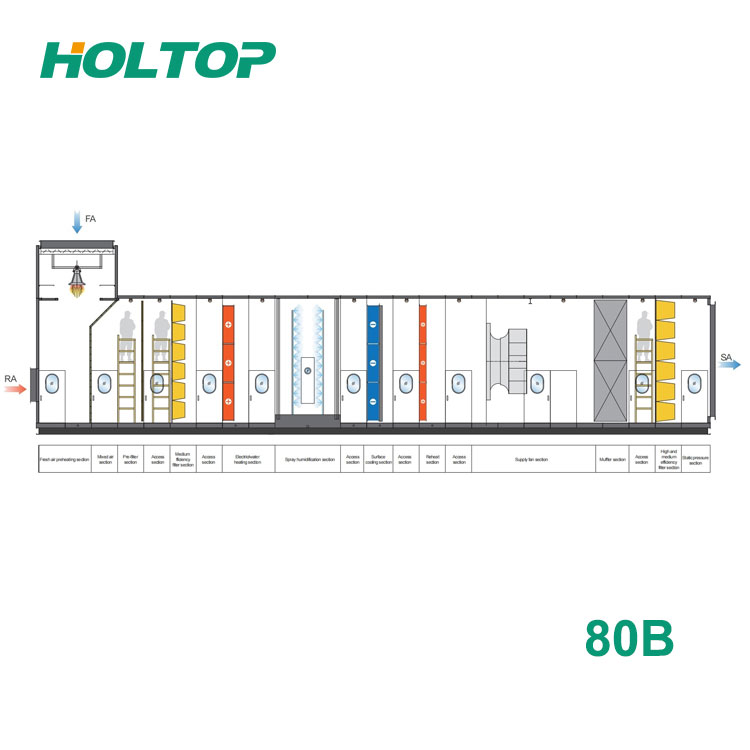

Adoption of High-Efficiency Air Handling Units (AHUs) for Maximum Output

Modern AHUs with higher Seasonal Energy Efficiency Ratios (SEER) improve airflow management while consuming less power. Retrofitting older units with high-efficiency models delivers immediate energy savings, particularly in facilities operating continuously.

Variable Speed Drives (VSD) for Energy Savings in Dynamic Load Environments

VSDs adjust motor speeds based on real-time demand, eliminating the energy waste associated with fixed-speed operation. Industrial plants using VSDs report up to 40% lower energy use in ventilation and cooling, according to efficiency benchmarks.

HVAC System Upgrades to Energy-Efficient Models: ROI and Payback Periods

Replacing outdated HVAC equipment with ENERGY STAR®-rated systems yields measurable returns. Upgrade costs are typically recovered within 4–7 years, with ongoing savings of $0.10–$0.20 per square foot annually in large installations.

Case Study: 30% Energy Reduction in Manufacturing Plant Using Optimized AHUs and VSDs

A Midwest automotive plant achieved a 30% drop in energy costs after integrating high-efficiency AHUs and VSDs. The $200k investment generated $60k in annual savings, demonstrating the scalability of such upgrades for heavy-industrial applications.

By prioritizing energy efficiency through strategic upgrades, industrial operators can achieve long-term cost reductions while meeting sustainability targets.

Predictive Maintenance and Smart Monitoring for Industrial HVAC

Predictive Maintenance and IoT Integration in HVAC Systems for Early Fault Detection

Industrial HVAC systems increasingly rely on IoT sensors these days to spot problems early on. These smart devices catch things like unexpected temperature changes and weird airflow patterns long before anything actually breaks down. Take vibration sensors installed on compressors for instance they often pick up signs of worn bearings about 10 to 14 days ahead of time when the system is still running normally. That gives technicians plenty of warning to schedule repairs properly. According to data from Cambridge Air Solutions back in 2023, facilities that adopt this kind of forward thinking maintenance strategy see roughly half the unplanned downtime compared to places that only fix equipment after it breaks.

AI and Predictive Maintenance in Building Systems to Minimize Downtime

Machine learning algorithms analyze operational data to forecast equipment failures with 92% accuracy. AI-driven platforms prioritize maintenance based on asset criticality and urgency, reducing response times by 35%. A 2023 study found that facilities using AI-augmented strategies cut annual maintenance costs by $18 per square foot and extended equipment lifespans by 2–4 years.

Routine HVAC Maintenance vs. Predictive Strategies: Cost-Benefit Analysis

Traditional quarterly maintenance costs average $48,000 annually for a 100,000 sq. ft. facility, whereas predictive programs cost around $32,000 and result in 60% fewer emergency repairs. The shift delivers ROI within 14 months by reducing:

- Energy waste from degraded components (12–19% savings)

- Overtime labor for after-hours breakdowns

- Inventory costs for emergency spare parts

Real-Time Monitoring With Smart Sensors in Industrial HVAC Networks

Wireless sensors monitor key parameters—such as refrigerant pressure and heat exchanger efficiency—every 15 minutes. A food processing plant in Ohio achieved 27% energy savings by integrating 120 sensors with its Building Management System (BMS), automatically adjusting setpoints when performance deviated more than 5% from baseline.

Controversy Analysis: Over-Reliance on Automation in Maintenance Planning

Despite the benefits, 42% of facility managers in a 2024 survey expressed concerns about:

- False alarms from immature AI models wasting technician time

- Cybersecurity vulnerabilities in IoT-enabled HVAC equipment

- Skill gaps in interpreting predictive analytics outputs

Balancing automated insights with human oversight is essential—systems requiring manual validation of high-risk alerts achieve 23% higher operator trust than fully autonomous platforms.

The HVAC maintenance service market is projected to grow at 7.42% CAGR through 2032, reflecting increased adoption of hybrid human-machine strategies.

Advanced Control and Energy Management Integration

Implementing Energy Usage Monitoring and Management Systems for Industrial HVAC

Industrial facilities can benefit from real time energy monitoring when it comes to keeping tabs on how their HVAC systems are performing. These setups spot problems like compressors turning on and off too much or fans running at inefficient speeds. The tech behind them usually involves smart sensors connected to the internet plus some kind of online analysis tool. Most plants see around 12 to maybe 18 percent less wasted energy each year without hurting production levels. Take one case we looked at recently where they integrated these systems into their microgrids. The results were pretty impressive actually, with almost half the usual energy consumption after implementing better ways to monitor and manage loads across different parts of the facility.

Integration with SCADA and BMS for Centralized Control

Connecting HVAC systems to SCADA (Supervisory Control and Data Acquisition) and BMS (Building Management Systems) allows centralized control across zones, prioritizing high-usage areas. Facilities using this integration report 15–20% faster response to thermal load changes, reducing energy spikes during peak production.

Data-Driven Decision Making Using HVAC Performance Analytics

Advanced analytics platforms process historical and real-time data—such as airflow rates and refrigerant pressures—to recommend load-balancing actions. Predictive algorithms can adjust setpoints in advance, cutting energy use by up to 25% in variable industrial environments.

Ventilation Optimization and Load Reduction Techniques

Strategies for ventilation optimization in large-scale industrial facilities

Optimizing ventilation requires strategic air balancing and demand-based adjustments. A model-driven approach using variable air volume (VAV) systems and real-time airflow monitoring can reduce energy consumption by up to 25% in large facilities according to recent studies in Applied Energy. Key strategies include:

- Zoning: Partitioning facilities based on occupancy and thermal loads

- Dynamic airflow adjustments: Using CO₂ sensors to modulate ventilation rates

- Pressure balancing: Eliminating over-ventilation in low-demand zones

Zoning and demand-controlled ventilation to reduce energy waste

Demand-controlled ventilation (DCV) aligns airflow with real-time occupancy, reducing energy use by 18–30% in industrial settings. Multi-zone systems with automated dampers and predictive algorithms ensure precise air delivery while preventing overventilation—a common inefficiency in legacy HVAC designs.

Heat recovery systems and their impact on net energy load

Integrating heat exchangers captures waste heat from exhaust air, reducing heating loads by 15–40%. Modern heat recovery ventilators (HRVs) offer payback periods under 3 years in cold climates, making them a practical solution for industrial decarbonization while maintaining air quality compliance.

Strategic Planning: Audits, Refrigerants, and Capital Investment

Energy auditing and consulting: Identifying hidden inefficiencies in industrial HVAC

Comprehensive energy audits uncover inefficiencies contributing to 15–30% of unnecessary energy use in manufacturing. These assessments evaluate airflow, thermal performance, and equipment degradation to guide upgrades. Third-party consultants often find overlooked opportunities—like sealing duct leaks or optimizing setpoints—that typically deliver payback within 12–18 months.

Benchmarking performance against industrial energy efficiency standards

Leading manufacturers benchmark HVAC performance against ISO 50001 and ASHRAE Standard 90.1 to identify optimization gaps. Compliant facilities report 22% lower energy intensity (kBtu/sq ft) than non-compliant peers. This approach supports targeted improvements in compressor efficiency (targeting 80% isentropic efficiency) and heat exchanger performance.

Cost implications of transitioning to low-GWP refrigerants

Replacing high-GWP refrigerants like R-410A with alternatives such as R-454B increases upfront costs by $8–$12 per ton but reduces long-term compliance risks. The EPA’s phasedown under the AIM Act mandates a 40% reduction in HFC production by 2024, creating $18–$25/ton carbon credit opportunities for early adopters.

Regulatory compliance and long-term savings in refrigerant management

Proactive refrigerant tracking helps avoid EPA fines exceeding $37,500 per violation under Section 608 of the Clean Air Act. Facilities using automated leak detection reduce annual refrigerant purchases by 35% and maintain 99% compliance with CARB reporting requirements.

Aligning HVAC investments with energy optimization and decarbonization goals

Phased capital planning that integrates high-efficiency HVAC with renewable energy systems can reduce Scope 2 emissions by 40–60%. A 2023 study showed such facilities achieve a 7.2-year ROI through utility incentives ($15–$20/sq ft) and operational savings.

Evaluating the cost-saving potential of advanced HVAC technologies

Variable refrigerant flow (VRF) systems deliver 30–50% energy savings in industrial applications compared to conventional systems. Smart pressure-independent control valves reduce pumping energy by 65% while maintaining ±1°F temperature stability in process cooling.

Trend analysis: How HVAC technology trends are shaping industrial investment

Heat recovery ventilator installations grew 142% from 2020–2023 as facilities leveraged 25–35% waste heat reuse potential. The shift toward AI-driven load forecasting now influences 58% of HVAC capital budgets, with predictive algorithms reducing seasonal energy spikes by 19% in temperature-sensitive manufacturing environments.

FAQs

What is the role of AHUs in industrial HVAC systems?

Air Handling Units (AHUs) are integral to HVAC systems as they manage airflow, reduce energy consumption, and improve efficiency, particularly when using high-efficiency models.

Why should VSD technology be implemented?

Variable Speed Drives (VSD) adjust motor speeds based on real-time demand, minimizing energy waste and significantly cutting energy usage in HVAC systems.

How can predictive maintenance benefit industrial HVAC systems?

Predictive maintenance uses IoT sensors for early fault detection, thus helping reduce unplanned downtime and maintenance costs while extending equipment life.

What are the benefits of real-time energy monitoring in HVAC systems?

Real-time energy monitoring identifies inefficiencies and helps reduce energy waste by providing accurate insights into HVAC system performance.

Table of Contents

-

Maximizing Energy Efficiency in Industrial HVAC Systems

- The Role of Energy Efficiency in Reducing Operational Costs for Industrial HVAC

- Adoption of High-Efficiency Air Handling Units (AHUs) for Maximum Output

- Variable Speed Drives (VSD) for Energy Savings in Dynamic Load Environments

- HVAC System Upgrades to Energy-Efficient Models: ROI and Payback Periods

- Case Study: 30% Energy Reduction in Manufacturing Plant Using Optimized AHUs and VSDs

-

Predictive Maintenance and Smart Monitoring for Industrial HVAC

- Predictive Maintenance and IoT Integration in HVAC Systems for Early Fault Detection

- AI and Predictive Maintenance in Building Systems to Minimize Downtime

- Routine HVAC Maintenance vs. Predictive Strategies: Cost-Benefit Analysis

- Real-Time Monitoring With Smart Sensors in Industrial HVAC Networks

- Controversy Analysis: Over-Reliance on Automation in Maintenance Planning

- Advanced Control and Energy Management Integration

- Ventilation Optimization and Load Reduction Techniques

-

Strategic Planning: Audits, Refrigerants, and Capital Investment

- Energy auditing and consulting: Identifying hidden inefficiencies in industrial HVAC

- Benchmarking performance against industrial energy efficiency standards

- Cost implications of transitioning to low-GWP refrigerants

- Regulatory compliance and long-term savings in refrigerant management

- Aligning HVAC investments with energy optimization and decarbonization goals

- Evaluating the cost-saving potential of advanced HVAC technologies

- Trend analysis: How HVAC technology trends are shaping industrial investment

- FAQs